Molded Pulp Packaging Suppliers: Offering Durability, Customization, And Sustainability

Environmental responsibility and sustainability are now important considerations in corporate decisions, especially when it comes to packaging. Molded pulp packaging, an eco-friendly alternative to traditional packaging materials like plastic and Styrofoam, is increasingly gaining traction across industries. Molded pulp packaging suppliers are at the forefront of this shift, offering durable, customizable, and sustainable solutions that meet modern business needs without compromising environmental integrity.

The Rise Of Molded Pulp Packaging

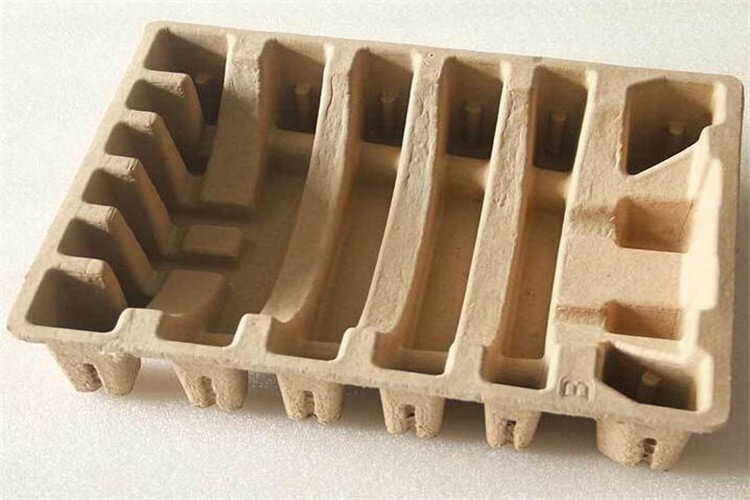

The molded pulp, also known as molded fiber, is a packaging material created from recycled paper, cardboard, or other natural fibers. It’s most commonly recognized in products like egg cartons, but its uses extend far beyond. Molded pulp is highly versatile, used in a variety of industries including electronics, food packaging, consumer goods, and medical equipment.

The process begins with shredding and pulping the raw materials, which are then molded into specific shapes through a series of vacuum, pressure, and heat treatments. The result is a durable, shock-resistant packaging solution that can be tailored to individual product specifications. Molded pulp packaging suppliers play a key role in this process, offering not just raw materials but the expertise and equipment necessary to produce high-quality, reliable packaging.

Durability: A Key Advantage

The longevity of molded pulp packing is among its main benefits. Many people may mistakenly think that because molded pulp is made from paper, it is inherently fragile or easily damaged. However, molded pulp is designed to be strong and resilient. It provides excellent cushioning and protection for fragile items, rivaling conventional materials like Styrofoam in shock absorption and rigidity.

This durability makes it an ideal choice for packaging electronics, glassware, and other fragile goods. Molded pulp also offers moisture resistance, which is crucial for food packaging and other products that may encounter liquids during transportation or storage. Molded pulp suppliers can design pulp packaging with specific durability standards, ensuring the right level of protection based on product needs.

Customization: Tailored To Your Needs

Molded pulp packaging suppliers offer a high degree of customization, allowing businesses to design packaging that fits their products perfectly. Unlike standardized plastic packaging, which often results in excessive waste due to oversized or ill-fitting designs, molded pulp packaging can be custom-molded to the exact shape and dimensions of the product it is meant to protect.

This level of customization not only enhances product safety but also improves brand presentation. Customized molded pulp packaging can be printed with logos, product information, and branding, allowing businesses to deliver a cohesive and professional image. With modern technology, suppliers can even create intricate designs, perforations, and textures in the packaging, further enhancing its aesthetic appeal and functional performance.

Sustainability: A Green Solution

Perhaps the most compelling reason to choose molded pulp packaging is its sustainability. Packaging solutions that minimize waste and lower carbon footprints are in greater demand as consumers and businesses become more aware of the effects they have on the environment. Molded pulp fits this bill perfectly.

Compared to materials like plastic, which are sourced from fossil fuels, molded pulp packaging has a far lower environmental effect because it is made from renewable resources like recycled paper. Additionally, molded pulp is completely compostable and biodegradable, which means it decomposes in the environment naturally without producing hazardous byproducts or adding to landfill garbage.

Moreover, the production process itself is energy-efficient and results in minimal waste. Any excess material generated during production can be recycled and reintroduced into the pulp, ensuring that waste is kept to a minimum. Many molded pulp packaging suppliers prioritize eco-friendly manufacturing practices, further contributing to the sustainability of the final product.

The Role Of Molded Pulp Packaging Suppliers

Suppliers are essential to the development of molded pulp packaging because they give companies the know-how, resources, and materials they need to produce high-caliber, environmentally friendly packaging. They assist businesses in creating packaging that not only safeguards the item but also supports their environmental objectives.

Molded pulp packaging suppliers often offer end-to-end services, from product design and prototyping to large-scale production. This comprehensive approach ensures that businesses get packaging solutions that are not only cost-effective but also environmentally friendly and tailored to their specific needs.

Conclusion

In a world where sustainability and product protection are increasingly important, molded pulp packaging suppliers offer a compelling solution. With the ability to provide durable, customizable, and eco-friendly packaging options, they are helping businesses reduce their environmental impact while delivering practical, cost-effective packaging. Whether you are looking to protect fragile goods, enhance your brand, or make a positive environmental impact, molded pulp packaging is a smart, sustainable choice that meets the demands of today’s market.